-40%

Arc Welder Refit Cold Spot Welding Machine Time Pulse Controller + Ears + Pedal

$ 63.33

- Description

- Size Guide

Description

Arc Welder Refit Cold Welding Machine Time Pulse Controller + Ear + PedalVideo will open in a new window

Using the eBay App? Paste link into a browser window:

[isdntekvideo]

Arc Welder Refit Cold Welding Machine Time Pulse Controller + Ear + Pedal For Imitation Laser Welding Stainless Steel Mold Cold Spot Welder

(FAST SHIPPING)

DESCRIPTION:

Length: 145 mm

Width: 85 mm

High: 40 mm

Argon arc welding machines and controllers cooperate well, and the whole cold welding machine has no difference. The integral cold welder is built into the controller panel.

Argon arc welder suitable for cold welding plate thickness:

160A argon arc welding machine: cold welding mainly about 0.5-1.1mm

200A argon arc welder: cold welding mainly about 0.5-1.2mm

250A argon arc welding machine: cold welding mainly about 0.5-1.3mm

300A argon arc welding machine: cold welding mainly about 0.5-1.8mm

Argon arc welder: cold welding mainly about 0.5-1.8mm 0.5-2.0mm

Installation Introduction:

Installation method (plug and play without dismantling machine)

Note:

The welding machine only adjusts the main current, argon delay is generally adjusted to "5 seconds ", and all other parameters are adjusted to "0".

Analysis of cold welding Principle (Important)

Welding is the process of melting metal by heat output and then cooling and recrystallizing the metal to form a weld.The output heat is provided by the welder. The output current of the welder and the duration of the primary welding determine the output heat of the primary welding.The material and thickness determine the amount of welding heat required.(The adjustment of cold welding parameters is the process of matching the heat required and the heat output of materials.)

Argon arc welding current is adjusted by pressing the gun switch by hand after the length of time to control the output time to spot welding so as to control the size of a heat output, such as the problem is that people control accuracy and speed is limited every time generally more stable control welding length must be at least above 0.3 seconds, thus argon arc welding welding the same thickness material can only choose small current to weld, because it is easier for a large welding current wear.

Cold welding is by precise control of welding time and welding interval time to millieri level (millisecond), the current size as needed to directly adjust (as far as possible to ensure large current short time see example 0), so as to accurately control the welding heat output.Since the welding time can be accurate to the millili level, the welding of the same thickness of material can be instantaneous with a shorter time and a larger current.Advantages of instantaneous welding: Because of the high current welding time and short welding time, the heat of the material is mainly concentrated in the welding spot, and the surrounding influence is small, in professional words, the heat influence area is small.

A smaller heat-affected zone has two benefits:

1. When the heat affected area is reduced to the covered area of argon, the welding spot will not oxidize black with air, and the welding spot will be white and smooth.

2. When the heat affected area decreases, the variation of the workpiece will also decrease accordingly. The well-adjusted parameters are far less than that of TIG arc welding (the variation can only be reduced and cannot be eliminated; it is a lie or not rigorous to say that the energy cannot be changed).As long as the welding gun moves and walks on the weld when the welder operates, the moving distance is consistent each time, the white bright smooth and consistent fish-scale pattern can be welded.

Case 1

For example, 0.8mm stainless steel can use 200 current welding time 0.075 seconds to welding, so the current large welding time short heat affected area will reduce the effect is good, can also use 100 current welding time 0.15 seconds to welding, so the current small welding time long heat affected area will increase the effect is not good.

Technical parameters

Name: Box arc precision welding controller

Service voltage :AC 220V±20% 50Hz

Model: SK - 12

Power consumed: less than 15W

Frequency: 1-20 hz

Host size :145 X 85 X40mm

Suitable for :99% argon welder refit

Main engine weight: 400G

Time mode: Welding time: 2-198ms;Interval time: 10~990ms

Frequency mode: Pulse mode: 1~20Hz;Pulse duty cycle: 1~99%

Memory retention :20 groups

Working mode: single point, continuous, argon arc welding

Accessories list: master controller, power & control line, specification, certificate.

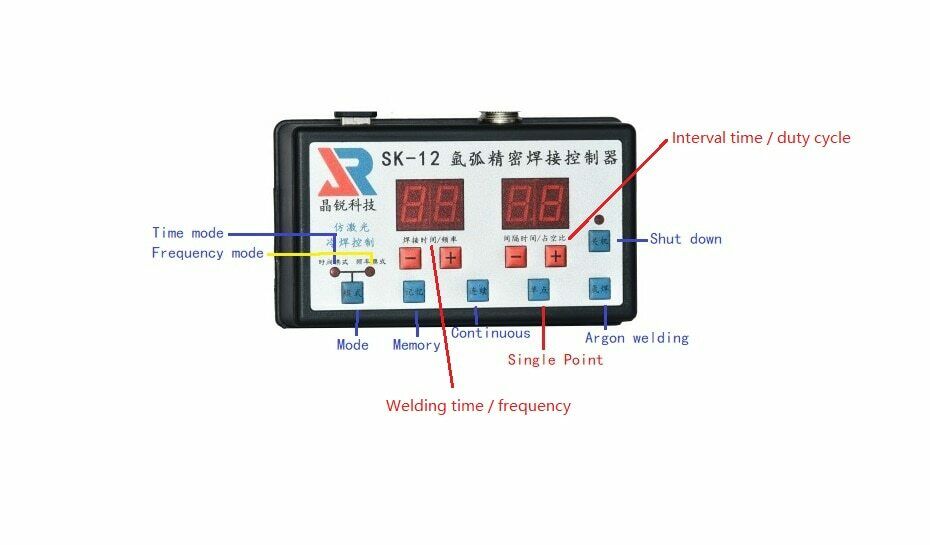

Panel introduction:

Button description:

1. Welding time/frequency display window: 99/20 display window.

2, welding time/frequency adjustment button: a total of 2 keys, respectively is adjustable and the small, welding time mode with 99 levels, each file Numbers for 2 MS (MS) (the number 50, for example, it represents the welding time 100 MS) frequency mode, a total of 20 file regulation, on behalf of welding the number of times per second (such as numerical 5, on behalf of the welding 5 per second)

3. Mode key: function switch between time mode and frequency mode

4. Memory key: there were 20 groups of memory, including time mode,10 groups, and frequency mode.The current data is automatically overwritten 1.5 seconds after the parameter is modified

5. Continuous key: when this key is pressed, the continuous indicator light will always be on. At this time, the working mode is continuous circular spot welding according to the adjusted parameters.

6. Single point key: When this key is pressed, the single point indicator light will always be on. At this time, the working mode is single point working mode.

7. Oxygen welding bond: when the button is pressed, the hydrogen solitarization indicator light is always on. At this time, the working mode is the working mode of hydrogen arc welding, that is, the same working mode as the original welding machine.

8. Interval time/duty cycle adjustment key: there are two keys in total, namely adjusting large and small, and the interval time adjustment is in 99 gears. The value of each gear represents 10MS (ms) (for example, the value of 50 represents the welding interval of 500MS), which will be displayed in continuous mode.In frequency mode, the duty cycle is adjusted in 99 gears, which represents the percentage of each welding time.This is mainly used for continuous work.The output time of the welder can be calculated by 1s/ frequency × duty ratio per second.

9. Power off key: When this key is pressed, the power off light will be on. At this time, the power off state will be maintained.

10. Interval time/duty cycle display window: 99 files in total.

Foot switch function:

Fixed work with foot switch control gun will be more stable, welding effect will be better, mobile work with a welding gun control.Both controls can be plugged in according to the needs of the job.

Three modes of operation: single point, continuous, argon welding

Three different operation mode selections to achieve a multi-purpose machine, no need to repeatedly disassemble, continuous mode works more easily.

Wide range of adaptive models

The new upgraded product can be compatible with MOS and IGBT models for more than 99% of argon arc welding models on the market, without affecting the original machine functions.

Benefits of using a controller:

Due to the large input energy of the common ARGON arc welder and the large thermal impact of welding on the workpiece, the workpiece is easy to change after welding, such as sheet penetration, discoloration and edge bite.The welder's technical requirements are very high, especially for thin stainless steel products!And the use of the controller of the modified argon arc welding machine successfully overcome the difficulties, whether novice or veteran, can produce welding smooth weld joints, improve product quality, reduce scrap rate, reduce cost, are widely used in some sheet like cabinets, doors and Windows, stainless steel water tank and hydraulic equipment, mould needs precision welding place!

1. The machine accurately controls the arc starting and arc stopping time of the welding gun, so as to unify the welding spot and weld depth and weld width every time.

2. Control the arc start and stop time so that the welding time can be controlled properly to meet the welding requirements

3. Press the welding gun switch in continuous functional state.The torch will weld automatically.Start arc a stop arc with a stop arc straight regular automatic welding.The arc start and stop time can be adjusted under this functional state.Can maximize welding efficiency.And ensure the uniformity of welding spot forming.

Argon arc precision welding controller How to use:

Sk-06 argon arc precision welding controller is easy to install, no need to dismantle the machine, the machine wiring can be connected to the control switch interface of argon arc welding machine.Due to the complete function of the machine, the use of the coupling control mode, strong adaptability, suitable for all kinds of welders, support more than 99% of the market sales argon arc welding machines (support MOS and IGBT).Therefore, there is basically no need to confirm your welder, whether it is multi-functional, whether it has built-in pulse, delay, air delay and other functions, it can be applied to the machine.As long as your welder and the parameters of the controller are adjusted properly (parameters refer to the manual or consult customer service personnel), the effect of cold welding can be achieved.

Application of cold welding controller for arc welding

1. Novice: After adjusting the parameters, novice welding will not weld through the workpiece, nor will it melt.As long as the solder joints are in alignment.That is a qualified teacher.

2. Improvement of welding forming: it is difficult to ensure that every welding spot is the same under the condition of manual welding, which leads to the disunity of welding spots.After the use of this product, after adjusting the parameters can make each welding spot unified, forming uniform fish scale pattern.

3. Small deformation: sometimes large deformation is caused by manual welding.Sometimes the deformation is small.And our machine controls the arc stop time, which can be controlled in the welding process when the workpiece is fused to stop immediately.Control the range of deformation.(Note: Argon arc welding is a melting pole welding.The work pieces are fused and welded together.So there will still be some deformation but it will be much smaller.)

4. Technical improvement of thin plate and thick plate: many masters welding too thin plate will occasionally weld through the phenomenon.It can be completely avoided by using this.0.6 More than the plate welding, adjust the parameters can achieve each welding out of color.Little deformation.Thick plates are white, blue, or gold in good condition when welded.Very beautiful)

5. Efficiency improvement: When the normal master welding the whole welding pass, he would click once and stop to weld again.In the case of the continuous function.Just move the tip of the welding gun and align it with the weld bead.Greatly improve welding efficiency and welding spot unity (suitable for kitchen utensils and appliances, table welding, fish-scale lines not to be mentioned below) mold repair: mold repair requirements are to control small deformation, or repair welding.This product can adjust the solder joint size.Can greatly improve the mold filling efficiency and forming requirements.

6. Use of automatic equipment: the sheet can't be welded if argon arc welding is used for automatic production.Because argon arc welding is used in automatic welding is pull welding.(that is, after arc has been welding arc).If the sheet is a little bit meager a pull welding will burn through.And the word that USES continuous function thin plate still can form a complete set automation to use.It's a melt pole weld.The work pieces are fused and welded together.So there will still be some deformation but it will be much smaller.)

Warm tips :

1. Import duties/VAT: Please check with your country\'s customs office to determine what these additional costs will be prior to bidding buying.

2. Import duties, VAT, Taxes and Charges are not included in the item price or shipping charges. These charges are the buyer\'s responsibility.

3. So if sent by express delivery such as DHL EMS SF TNT FEDEX ,you might need to pay the tax for your country .

SHIPPING

Items will be shipped out within 3-5 business days by

International AirMail with Tracking

after the payment is cleared by PayPal.The arrival time depends on your location.

This time may get longer due to special holidays and various clearances of the customs on both sides. Delivery time usually will be 14-35 business days. If you didn't receive your package within this time schedule, please do not hesitate to contact us.

PAYMENT

We accept payments only via Paypal.

We will ship to ebay's address only. Please make sure your address on ebay is the same as your shipping address before you pay.

RETURNS / EXCHANGES / REPLACEMENTS

All items will be checked carefully and packaged in good condition.But if the product is defective or damaged upon arrival, please contact us immediately.

Returns accepted within 30 days of delivery date and item must be in original new condition, not worn or altered in any way with attached tags & wrap. Otherwise the deal is final. Return shipping must be paid by the buyer.

CUSTOMER SERVICE

Our goal is to provide high quality products for a good competitive value, backed by excellent customer service.

We will be happy to resolve any issues you may have in a cordial and friendly manner.we will try our best to solve any dispute and try our best to satisfy you. If you are not satisfied with our product, please contact us first.

Integrity is of prime importance to us. We will leave Positive Feedback as soon as the transaction has been completed.

CONTACT US

Feel free to contact us if you have any questions. Your positive feedback is highly appreciated. Please let us know before leaving any negative feedback.

Please give us the opportunity to resolve any problems.Please contact us via eBay for any comments, questions or suggestions that you may have,

We will be happy to assist you.